Is used in materials with low tensile strength which makes threads more Most commonly used type for general engineering applications. Thread interchangeability among these three nations. Mean values given in page 897 of Machinery's Handbook.įorm used by the United Kingdom, Canada, and the United States to obtain screw Note 3: Value is obtained by linear interpolation/extrapolation of

ROLL TAP DRILL CHART PLUS

Note 2: Equals drill size decimal equivalent plus expected amount of Parameters table, the effect of drill oversize will be taken into account in tap drill bit selection. Note 1: If the "Include Oversize" checkbox is ticked in Input Roll tappingĭisplaces metal from the hole walls to form the threads so cutting tap drillĮxpected Hole Size (Including oversize) 2 Roll tapping is a method to be applied to relatively ductile metals such as low-carbon steel, leaded steels, austenitic stainless steels, wrought aluminum, magnesium, copper, and ductile copper alloys.įor roll tapping, cutting tap drill sizes should not be used. The threads produced with roll tapping are stronger than cut threads because the grains are continuous and unbroken, and the displaced metal is work hardened. Roll tapping eliminates the problem of chip disposal. Roll tapping is a process which forms a thread in the hole by displacement of the material into the desired size and pitch.

ROLL TAP DRILL CHART FULL

Desired thread size and % of full thread are input parameters for the calculator. Calculations are done according to roll form tap drill charts which are given in the Machinery's Handbook. The result is 4.0 mm - 0.8444 mm = 3.1666 mm, which is the necessary diameter for the drilled hole.Roll Form Tap Drill Chart Calculator for calculation of recommended roll form tap drill sizes for Unified threads.Subtract the result from the thread diameter (4.0 mm).Match this row to the 65% thread percentage column.Look for the 1.00 mm pitch in the chart's first column.For metric threads, the recommended thread percentages are 65% and 70%.įind the drilled hole size for a 65% thread on a 4 mm x 1.00 (M4) tapped hole:.Similar to the standard tap and drill section (see above), use the two formulas below to calculate the necessary size of the drilled hole.Look up the desired pitch and thread percentage to find the corresponding outer diameter.The tap and drill chart below is for Metric threads. 5 millimeters, the double thread depth is 1.0 millimeter. In the second method, double thread depth means twice the depth of the thread.For either formula, when inputting thread percentage, use, for example, 65% instead of 0.65.

Use the two formulas below to calculate the necessary drilled hole size in inches.The recommended thread percentage is 65%, 70%, and 75%.Thread percentage is the percentage of a bolt's shank that has threads.Look up the TPI and desired thread percentage to determine the corresponding outer diameter.

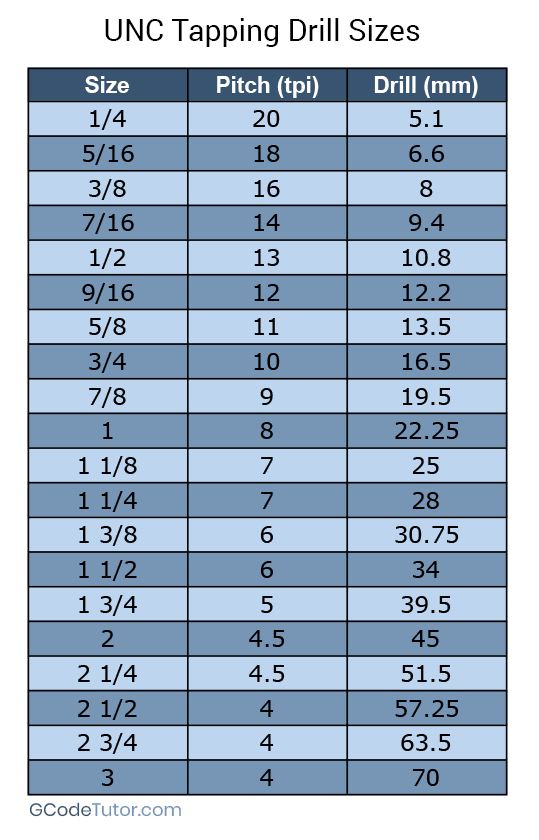

The chart below is for standard gauge threads (inch).

ROLL TAP DRILL CHART HOW TO

The following chart describes how to determine the size of standard male threads when making a bolt or threaded pipe.

0 kommentar(er)

0 kommentar(er)